UNMET NEED

Thermoplastics are becoming increasingly popular due to their recyclability and ease of processing. The thermoplastic composite market itself is valued above 30 B$ and continues to grow at 7% CARG. Sectors such as aerospace & defence, transportation or oil & gas are increasingly turning to these high-performance materials for new composite parts assembly and repair methods that align with waste reduction targets and more sustainable manufacturing and life-cycle management practices. However, welding and repairing thermoplastic parts takes time and often requires considerable skills and resources, not to mention the acquisition and maintenance of expensive equipment.

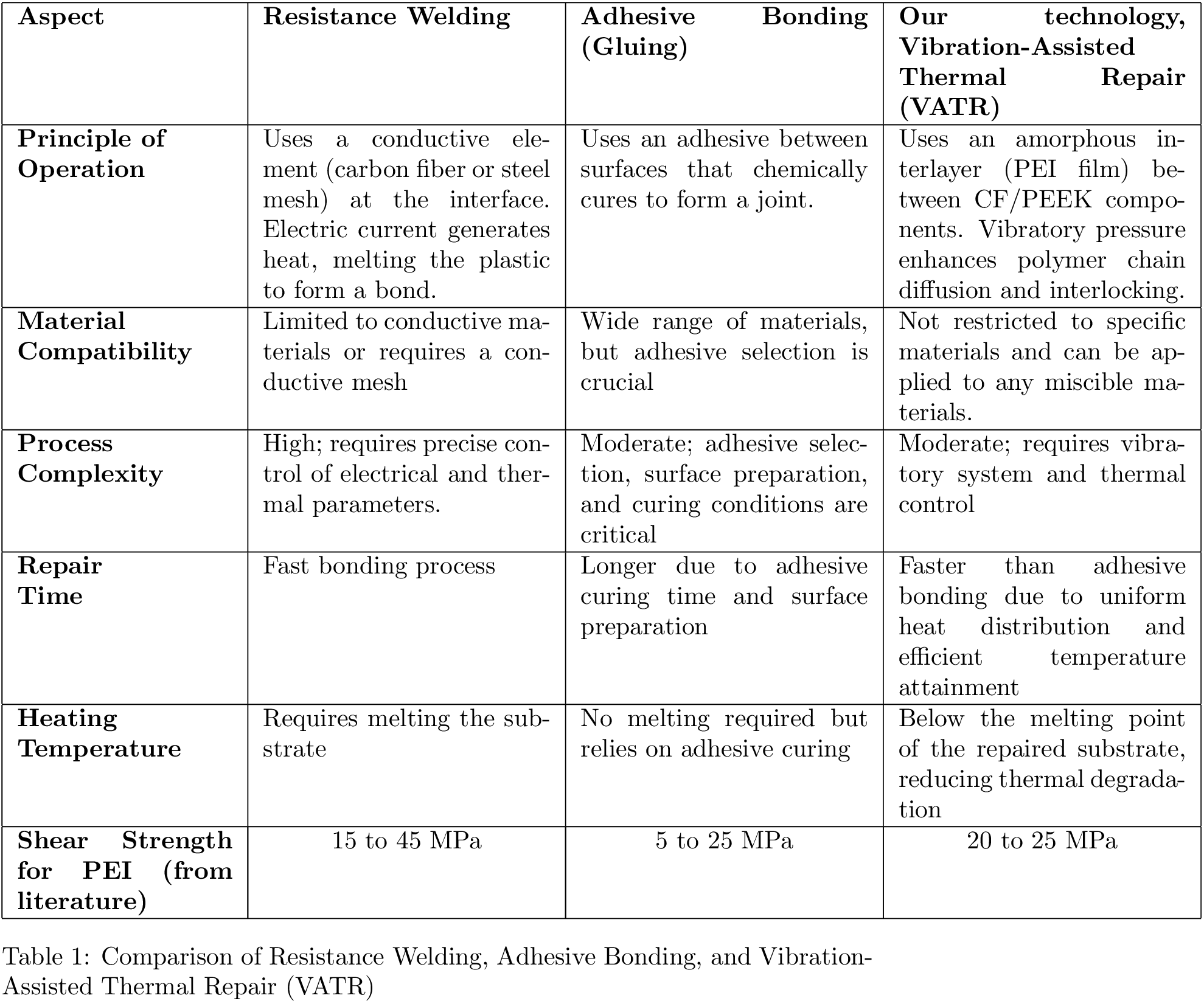

While factors like raw material costs still limit the adoption of thermoplastics, the high cost of replacing high-end composite parts compared to repair costs presents a significant opportunity. In industries like aerospace where this tipping point is commonly reached, the introduction of automated, low-cost, high-performance welding processes could drive the increased adoption of thermoplastics.