UNMET NEED

To address labour shortage and work arduousness, manufacturers must invest massively into robotics and automation. Small and medium size companies do not necessarily have cash flows to invest in robotization. Collaborative robot technologies offer a great compromise between solving labour issues and get a quick return on investment while investing in innovative technologies.

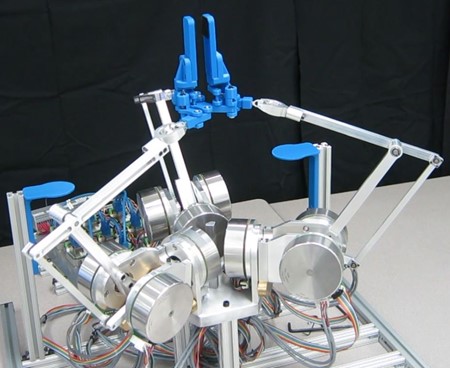

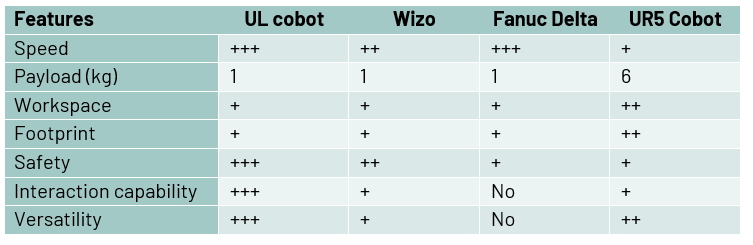

As a new trend in manufacturing industry, cobots should be easy to handle, efficient, high speed or payload, intuitive, compact, safe and have a short-term payback. Current serial cobots do not have all these features.