UNMET NEED

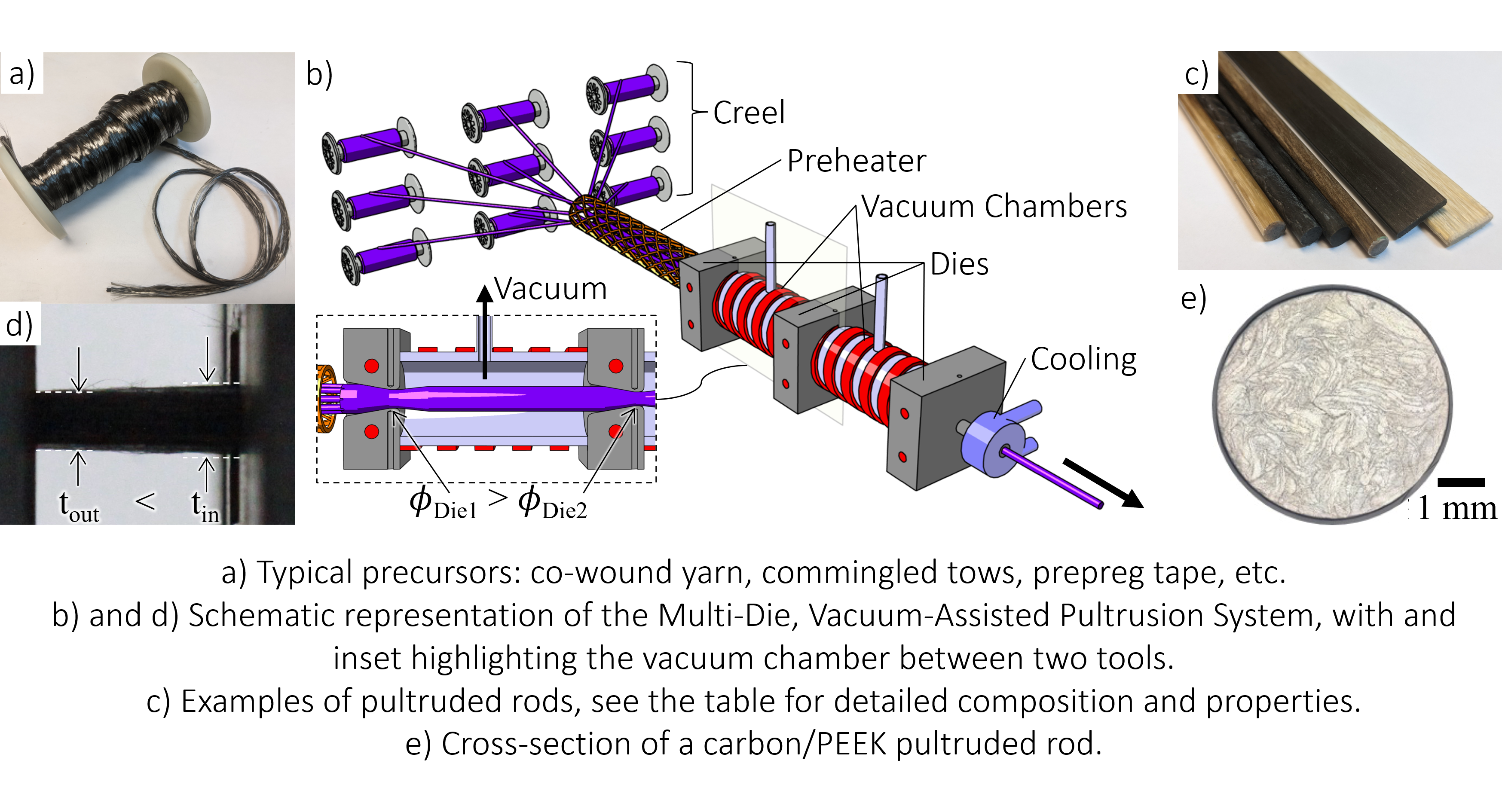

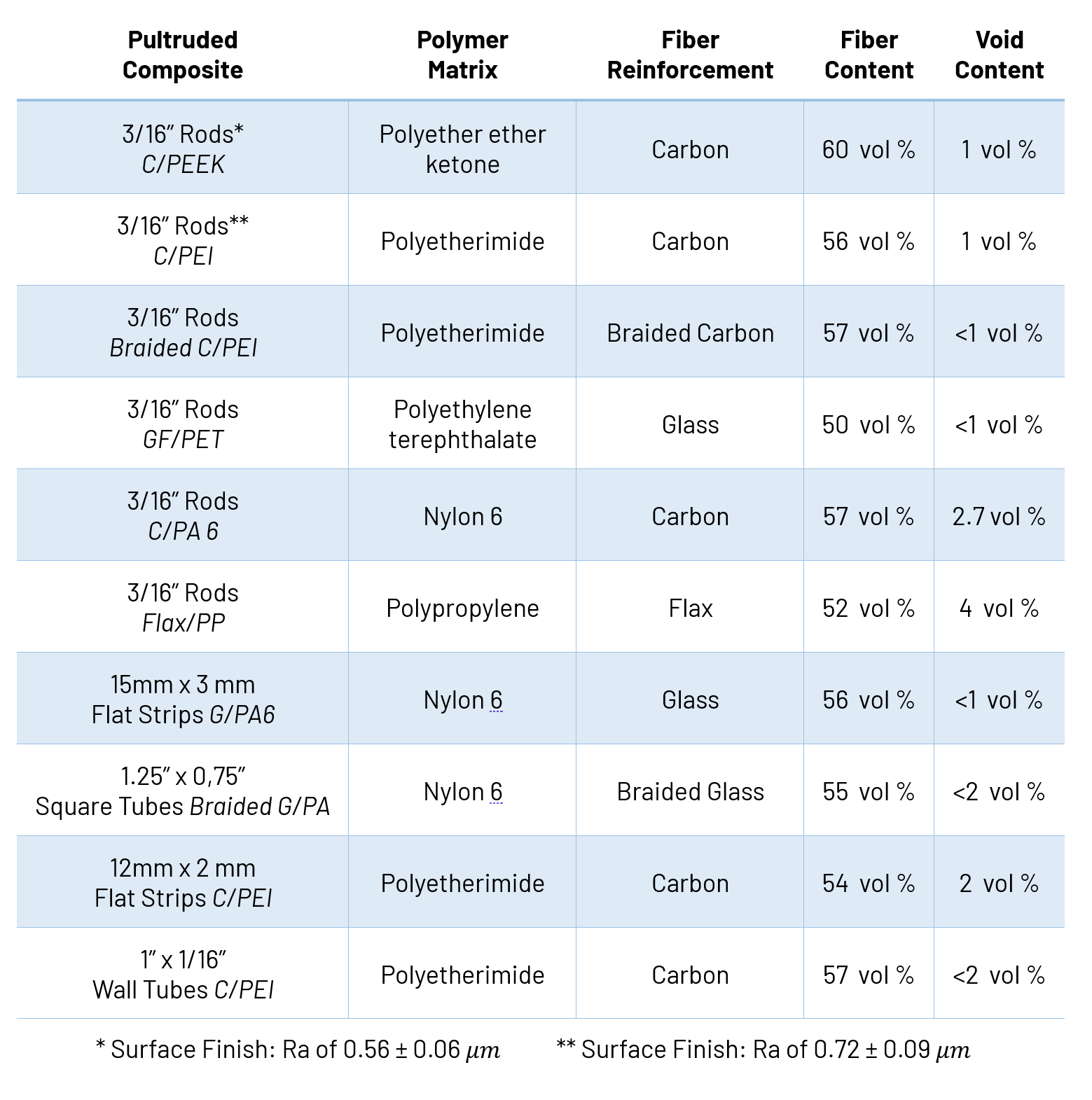

The quest for scalable production of composite materials—ranging from rods and beams to intricate profiles like window frames—demands an advanced manufacturing solution. Pultrusion has traditionally been the method of choice. However, conventional pultrusion methods, reliant on thermoset resins and glass fibers, fall short due to their lack of recyclability, inability to be welded, and non-reusability. The escalating demand for safer, greener and more adaptable products today calls for a transition towards thermoplastic resins, enriched with a wide spectrum of reinforcing fiber yarns, to overcome these limitations. Existing pultrusion systems lag in delivering the needed quality standards, especially in terms of high reinforcement content, minimizing porosity, and securing unparallel surface finishes, all while maintaining high throughput and profitability.