TECHNOLOGY OVERVIEW

Professor Bodkhe and her team have tackled these challenges through an innovative approach. They dispersed barium titanate (BaTiO₃), known for its piezoelectric properties, into PVDF in its natural phase (not inherently piezoelectric). The new composite achieves a piezoelectric coefficient of approximately 18 pC/N, comparable to commercial PVDF.

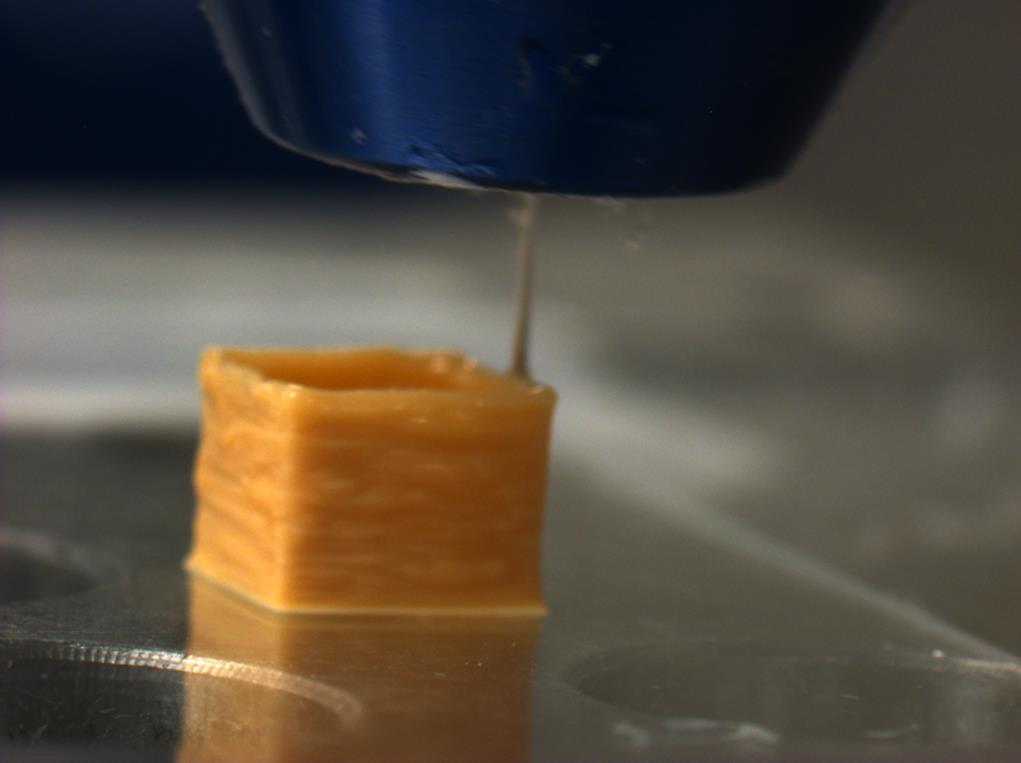

Sensor fabrication is completed in a single step by co-extruding piezoelectric ink and a silver paste. The advantages are:

1. For prototyping : Custom shaped sensors in no time

2. For manufacturing : Efficient and low cost

3. Robust and durable sensors

4. Ease of integration into other polymers and composite structures

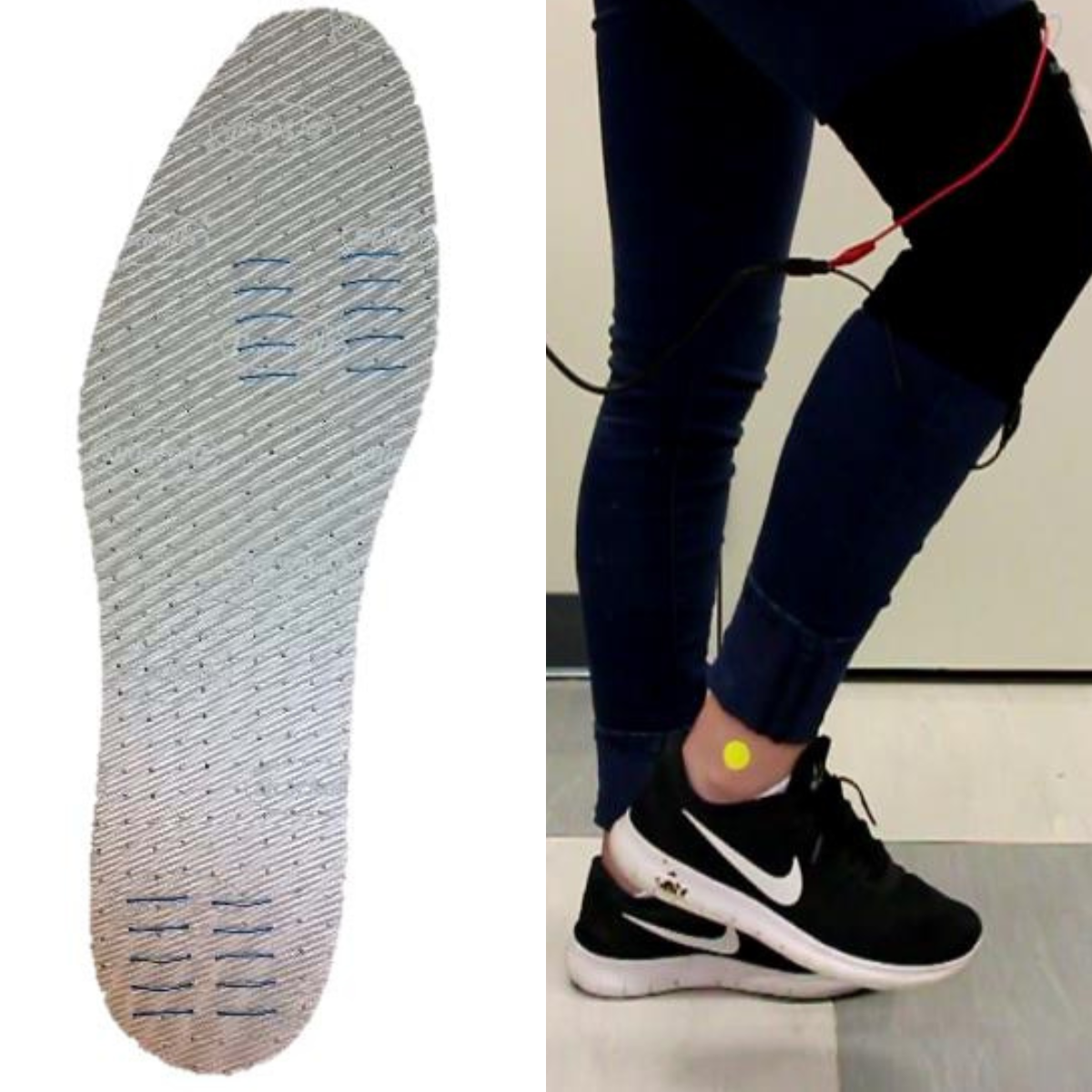

The technology has already been tested and proven effective in biomedical and mechanical applications, including breath monitoring, airflow sensing and structural health monitoring of composites.

Our technology unlocks piezoelectric materials for industrial applications requiring small, flexible and customizable sensors produced by robust dans low-cost manufacturing. Contact us to discuss your project and applications!

COMPETITIVE ADVANTAGES

- 3D printable custom-shape

- One step and Cost-effective manufacturing

BUSINESS OPPORTUNITY

- Technology available for licensing

- Seeking industrial application partners

- Eligibility to government financing for industry/academic maturation program

MARKET APPLICATIONS

- Piezoelectric sensors

- Industrial sensing

- IOT devices

- Biomedical sensors

IP PROTECTION

- US Patent (here)

- CA patent application