UNMET NEED

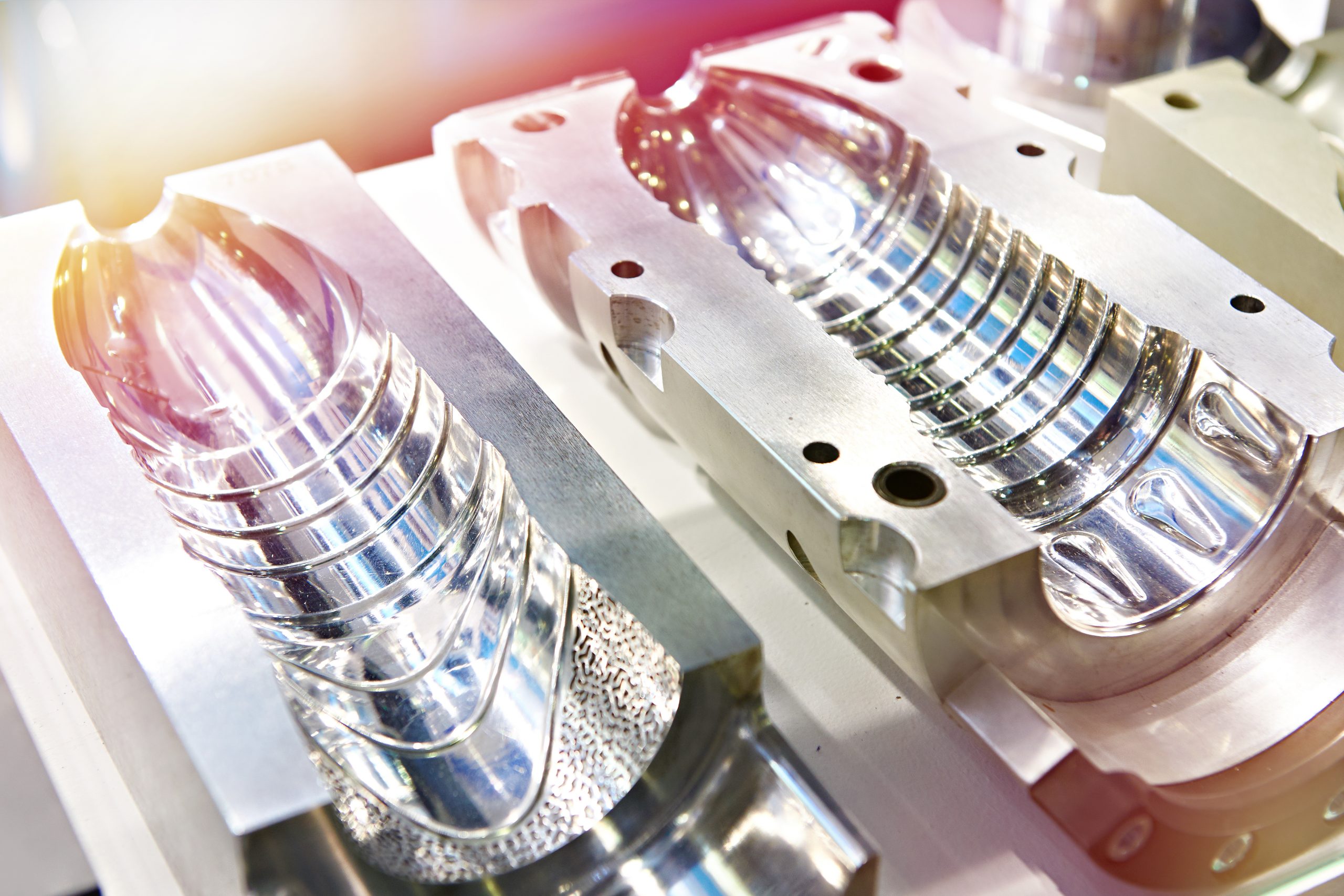

Metal injection moulding (MIM) is a manufacturing technology that produces dense metal parts from powders with mechanical properties equivalent to machining.

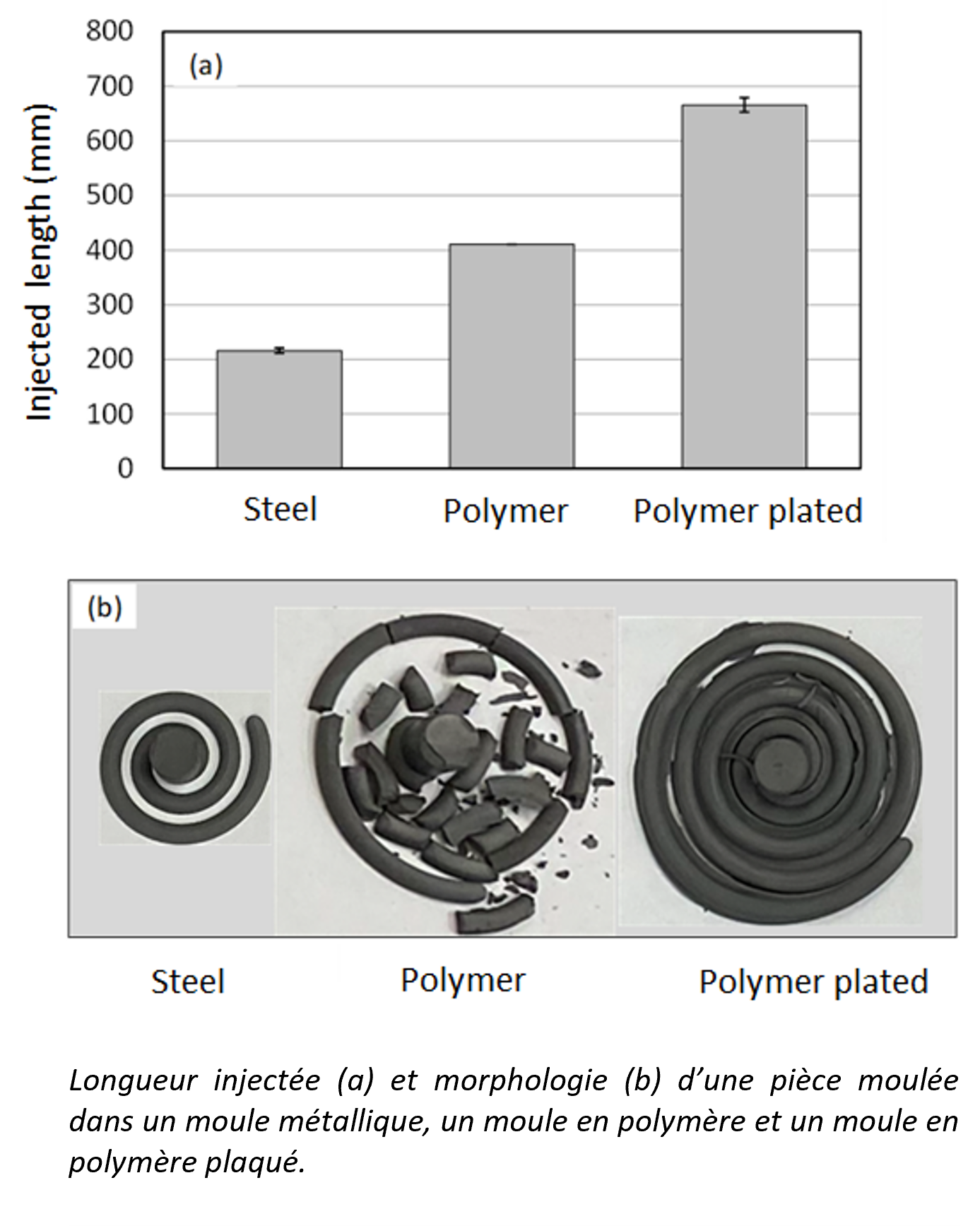

The molds can be made of metal or plastic. The objective of a mould is to increase the mouldability of the mixture and to decrease the sticking of the mixture with the mould.

In this sense, the greater the moldability, the more complex the shape of the injected part can be. Also, the lower the sticking (or absent), the simpler the demolding of the part is. On the one hand, the use of an all-metal mold decreases the bonding but also the moldability, and on the other hand, the use of an all-polymer mold increases the moldability but also the bonding.

The industry uses metal molds to avoid sticking. On the other hand, this solution forces manufacturers to accept a decrease in the moldability of their mixtures.